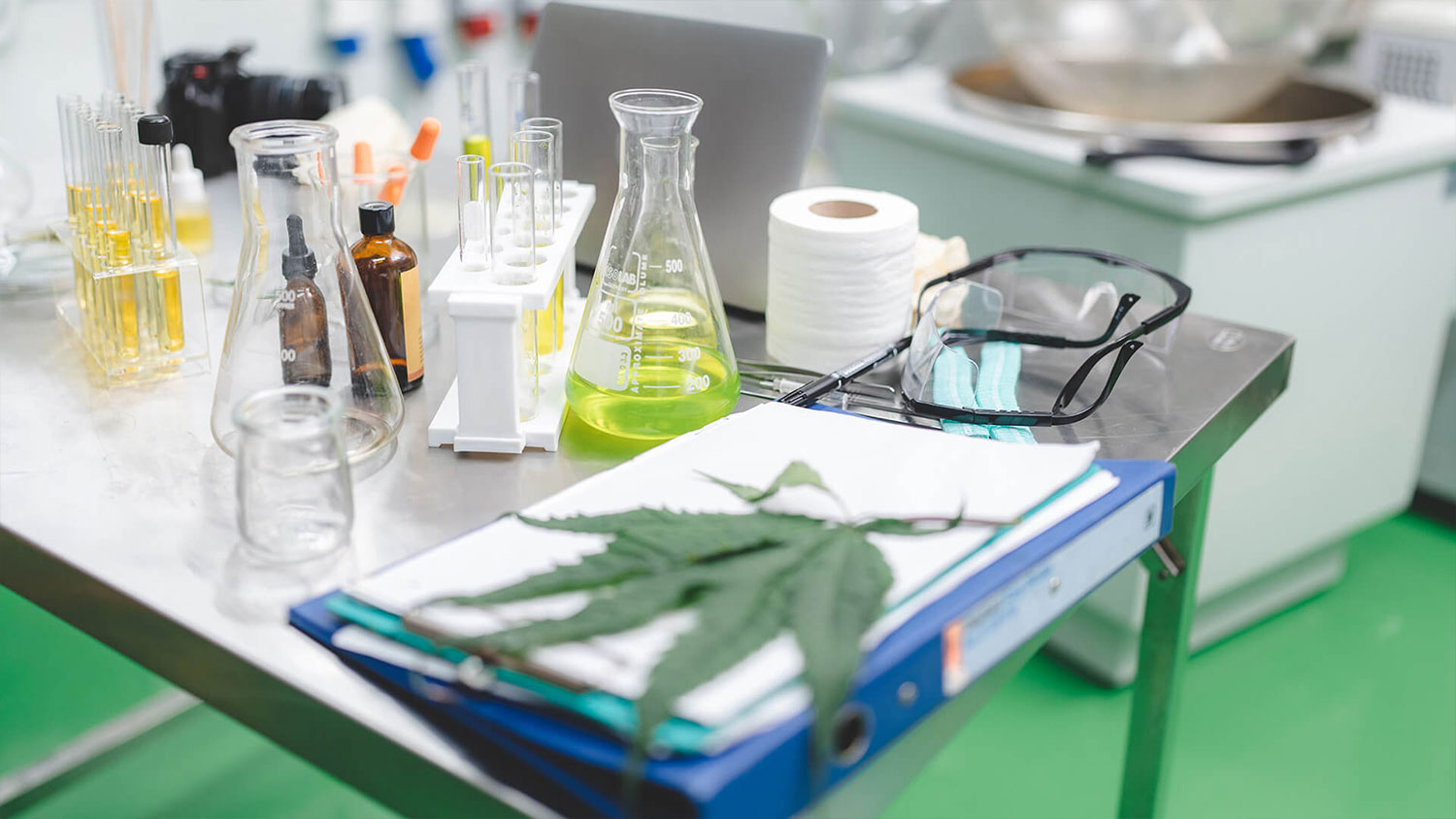

Biomass Post-Processing Solutions

We are process designers who can help you create the right formulation.

Our post-processing solutions enable you to deliver the highest quality products.

-

Winterization

Winterization removes unwanted materials, such as fats and waxes, from extracts. This process involves dissolving the extract in a solvent, such as ethanol, and then freezing it. The unwanted materials will then precipitate out of the solution, leaving behind a cleaner extract.

-

Filtration

Filtration is used to remove impurities and particulate matter from flower extracts. This process involves passing the extract through a filter, which can be made of various materials such as activated charcoal or silica.

-

Solvent Recovery

Solvent recovery is the process of removing solvents used in the extraction process, such as ethanol, so that they can be reused. This is typically done through a distillation process, where the solvent is heated and evaporated, and then condensed back into a liquid form.

-

Decarboxylation

Decarboxylation activates the psychoactive compounds in flowers, such as THC. This process involves heating the biomass at a specific temperature for a certain amount of time, which causes a chemical reaction that converts non- psychoactive compounds, such as THCA, into psychoactive compounds.

-

Distillation

Distillation is used to separate and purify different components of a flower extract, such as THC and CBD. This process involves heating the extract to its boiling point, and then collecting and condensing the vapors produced.

-

Isolation

Isolation separates specific compounds from flower extracts, such as THC or CBD in its purest form. This process can involve various techniques, such as chromatography, which separates different compounds based on their physical and chemical properties.

-

Remediation

Remediation is used to remove contaminants from flower extracts, such as pesticides or heavy metals to make the flower products safe for consumption.

-

Formulation

Formulation allows creating specific medical products, such as edibles or topicals, by combining different flower extracts with other ingredients. This process involves determining the desired potency and effect of the final product, and then creating a formulation that achieves those goals.