Supercritical Fluid Extraction Systems (CO2 Extraction)

Extract a pure, clean and safe product using Supercritical Carbon dioxide.

We design and build state-of-the-art systems that improve efficiency, yield, product quality and purity, while reducing manufacturing cycle time and increasing inventory turnover. Our automatic systems can be easily operated with minimal manpower, and equipped with recipe management and integrated intelligence.

Extract a pure, clean and safe product using Supercritical Carbon dioxide.

Eliminate the need for additional processing and increased cycle time using Cryo-Ethanol.

Extract high-quality trichomes.

Biomass Drying, Grinding and Storage for maximum yield and purity.

From product purification to palletizing and end product packing.

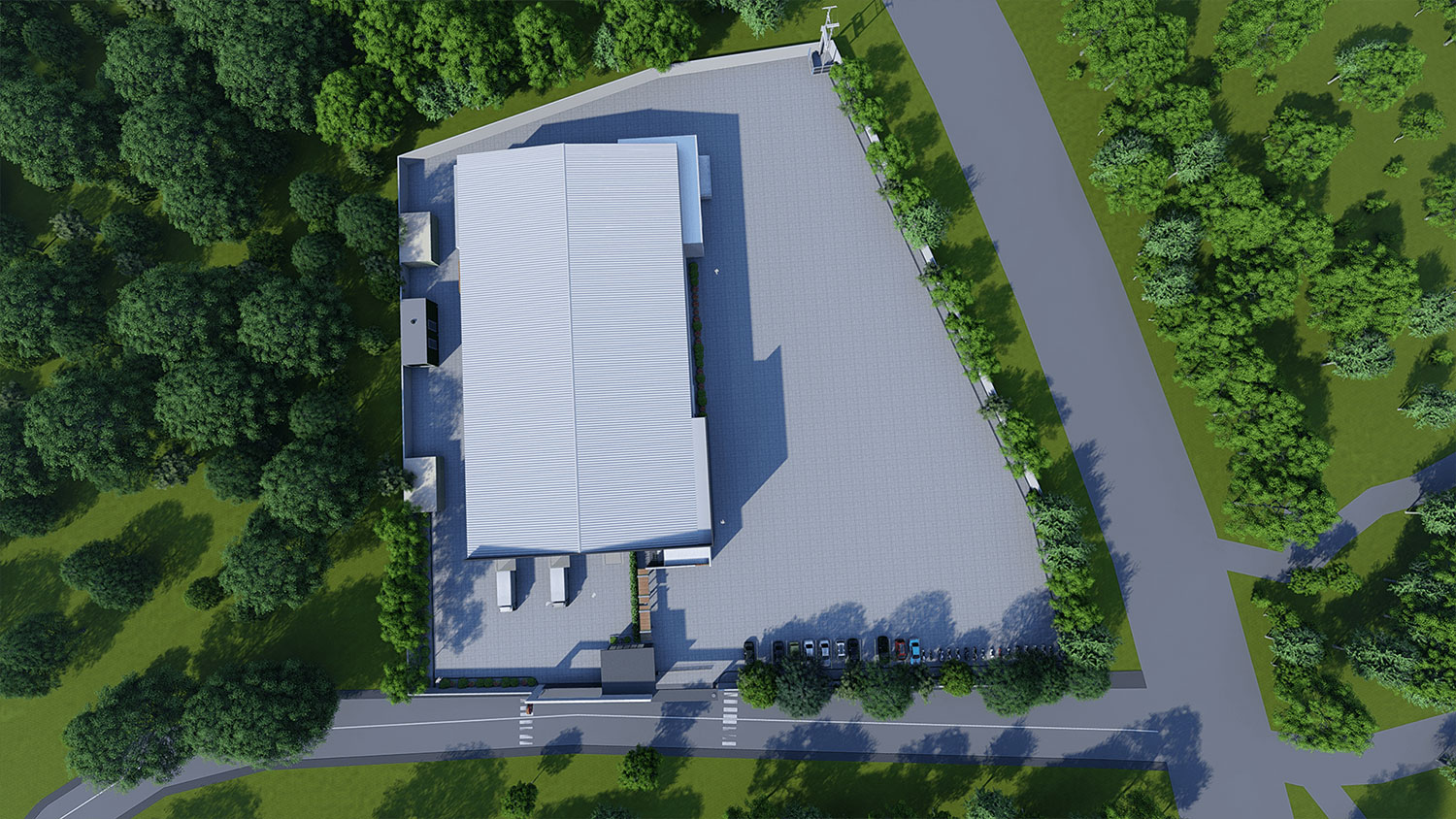

We help you with designing your facilities and systems to adhere to GMP (Good Manufacturing Practice) standards.

We are your single source solution - your one stop shop for converting your business case into a functioning system, from concept to commissioning.

We are committed to helping our clients navigate the nitty-gritty of the extraction process from critical planning aspects to financial planning, turnkey system commissioning to successful operations with end-to-end accountability.

Modern industries rely on a vast array of products (target molecules), and extracting them efficiently is crucial. Here are some comprehensive extraction solutions for various needs:

Many companies specialize in developing and supplying extraction solutions. Selecting the correct extraction equipment that aligns with your requirements is the key.

In today's competitive industry, efficient extraction solutions are not just a convenience, they’re a necessity. Here’s why a efficient solutions are important:

Efficient extraction solutions contribute to higher quality products, lower environmental impact, and ultimately, a strong and sustainable business model.

Buffalo Extraction Solutions specializes in turnkey extraction solutions for various industries. They offer cutting-edge systems for both cryogenic ethanol and supercritical CO2 extraction, ensuring high yield, purity, and efficiency. Beyond extraction, their services encompass pre-processing, post-processing, facility design, and consulting. With a focus on GMP compliance and customer support, Buffalo Extracts empowers businesses to produce top-quality products.

Here are the USPs of Buffalo Extracts’ extraction solutions:

Customized extraction solutions are becoming increasingly important in the extraction industry. This includes designing an extraction process specifically tailored to the unique characteristics of the product that is targeted. Customization according to your unique needs achieve the following goals:

Many companies specialize in developing and supplying customized extraction solutions. Consider consulting with such companies to identify and best fit your customization requirements.

Following are some types of the extraction solutions:

Each of these extraction solutions has its advantages and pitfalls. Selection of the process depends on the specific requirements of the extraction process.

Modern industries rely on the efficient extraction of valuable products from raw materials. These extraction solutions maximize yield, boost product quality, and speed up production. They also minimize waste and environmental impact. Integrating them involves assessing the needs, researching options, planning for smooth workflow, and training your team. By optimizing the process and staying updated, you can unlock a competitive edge and ensure long-term success.

These days, industries offer the following extraction solutions:

Buffalo Extraction Systems has developed an extraction solution for a prestigious University to extract various products. A certified supercritical fluid extraction (SCFE) system enables precise extraction of various products from various raw materials. It is designed for rapid loading and unloading, making it suitable for laboratory-grade research.

Built as a pilot scale plant for research and testing, the key features of this extraction solution are as follows:

The future of extraction solutions is likely to be shaped by a focus on efficiency, sustainability, and targeting specific compounds. Here are some key trends to watch:

Buffalo Extracts is a specialist extraction solutions provider. Our systems and technicians are known for: