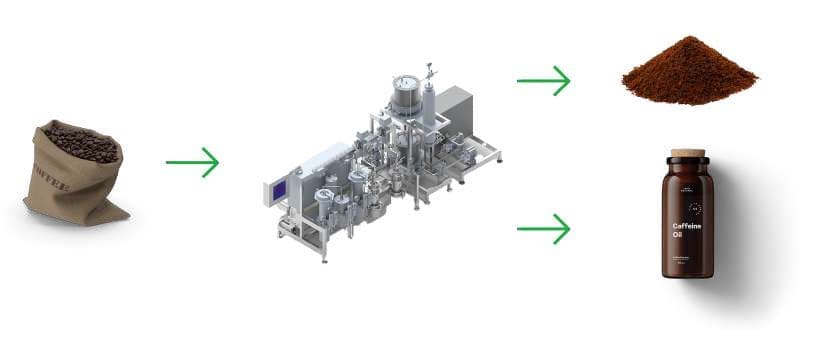

Coffee Extraction: Getting the most out of every Coffee bean.

Why Coffee?

The food, pharmaceutical and chemical industries has seen an immense demand for coffee extracts. Products containing 'natural' caffeine are generally perceived to be healthier than those containing 'synthetic' caffeine. Carbon dioxide (CO2) supercritical fluid extraction is a viable solution to get 'natural' caffeine from coffee, with valuable by-products such as Decaf coffee. Thinking beyond the beverage allows manufacturers to unlock the full potential of Coffee beans with extracts fetching up to 50x more than the produce.

The Extraction Advantage

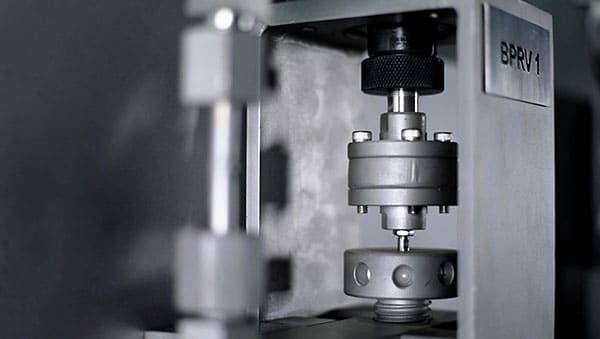

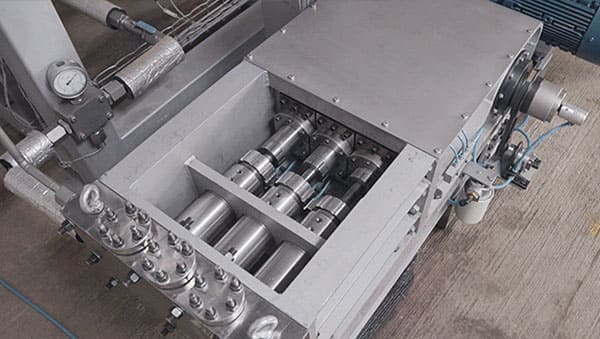

Extraction using supercritical carbon dioxide is a highly selective process. It only extracts the Caffeine compound and leaves the other flavour precursors (such as carbohydrates and peptides) in the bean, delivering superior quality and yield of products at low pressures and near-room temperature, making it a cost-effective solution in the Coffee Extraction business.

Moreover, SCFE preserves the purity of the ingredients without loss of heat-sensitive and volatile components, and is free of residual solvent and microbial contaminants.

Requirements in Extraction

- Lower adulteration in extraction process.

- The extracted solvent should have higher bioactive and lower residues.

- The output should be chemical free.

- Multiple recipe selection.

- Clean, safe and Green Technology.

- Robust process and monitor controlling.

- Operational safety.

- Minimal human intervention.